ENCIRCLE HYDRO

Drying logs and moisture mapping for water damage restoration

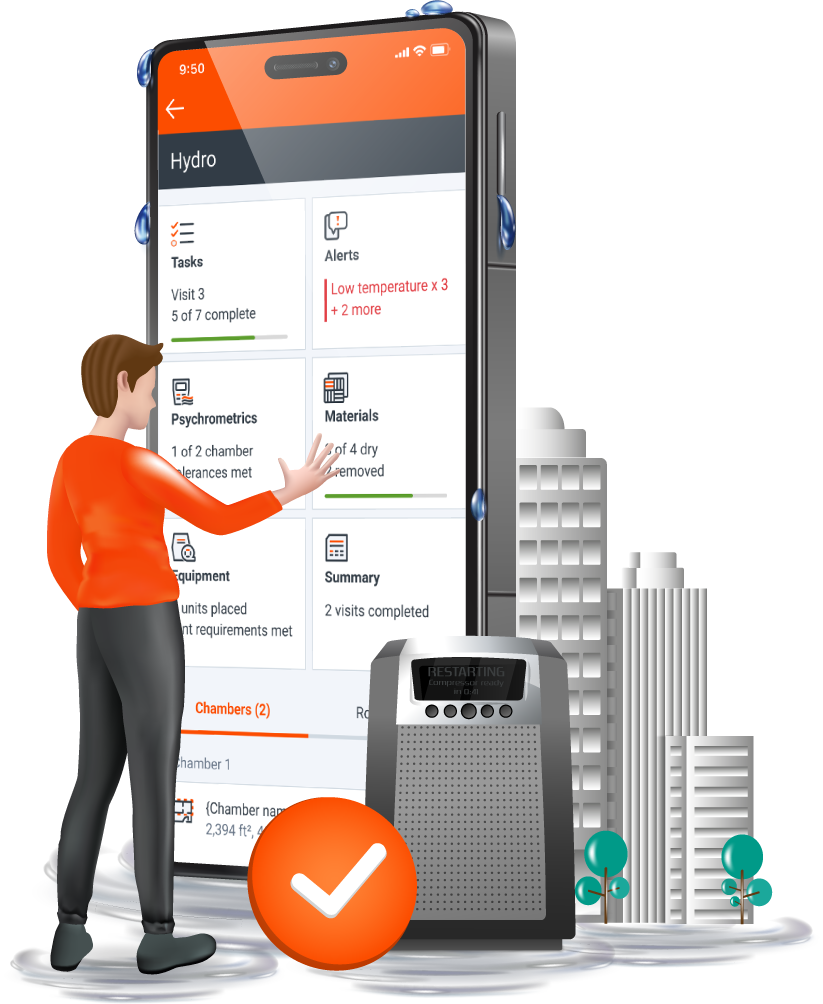

A mitigation checklist for field teams to dry and document without juggling multiple apps.

Set up jobs based on the S500 standards

Auto-calculate equipment needs

Immediately know if drying is off track

TRUSTED BY LEADING RESTORERS

NATE JUDY General Manager | Tobins Restoration“Hydro has created more consistency in our documentation and the technicians love how easy it is to use.”

BRENT WERNER President | Werner Restoration Services Inc.“I love this feature of Encircle. I’m going to put my moisture point in, I’m going to take my dehu reading, and then I’m going to attach a timestamped photo. You can’t argue with that.”

JOHN WOODS President | Crossroads Property Rescue“As badly as we wanted to go paperless, there just wasn't a system out there for us to do that, until Hydro.”

EVAN MACFAWN Senior Vice President, MacFawn Fire & Flood Restoration“I know that every project a Hydro report shows up on, there's no question about equipment calculation.”

Put a drying expert in the hands of every field tech.

Keep water jobs on track.

- Tolerances and drying goals

Establish a drying plan and set tolerances for temperature, humidity and moisture content. - Alerts and recommendations

Receive in-the-moment alerts when readings fall outside of defined tolerances. - Remote job review

Review job progress from anywhere with real-time visibility. Review job progress from anywhere with real-time visibility.

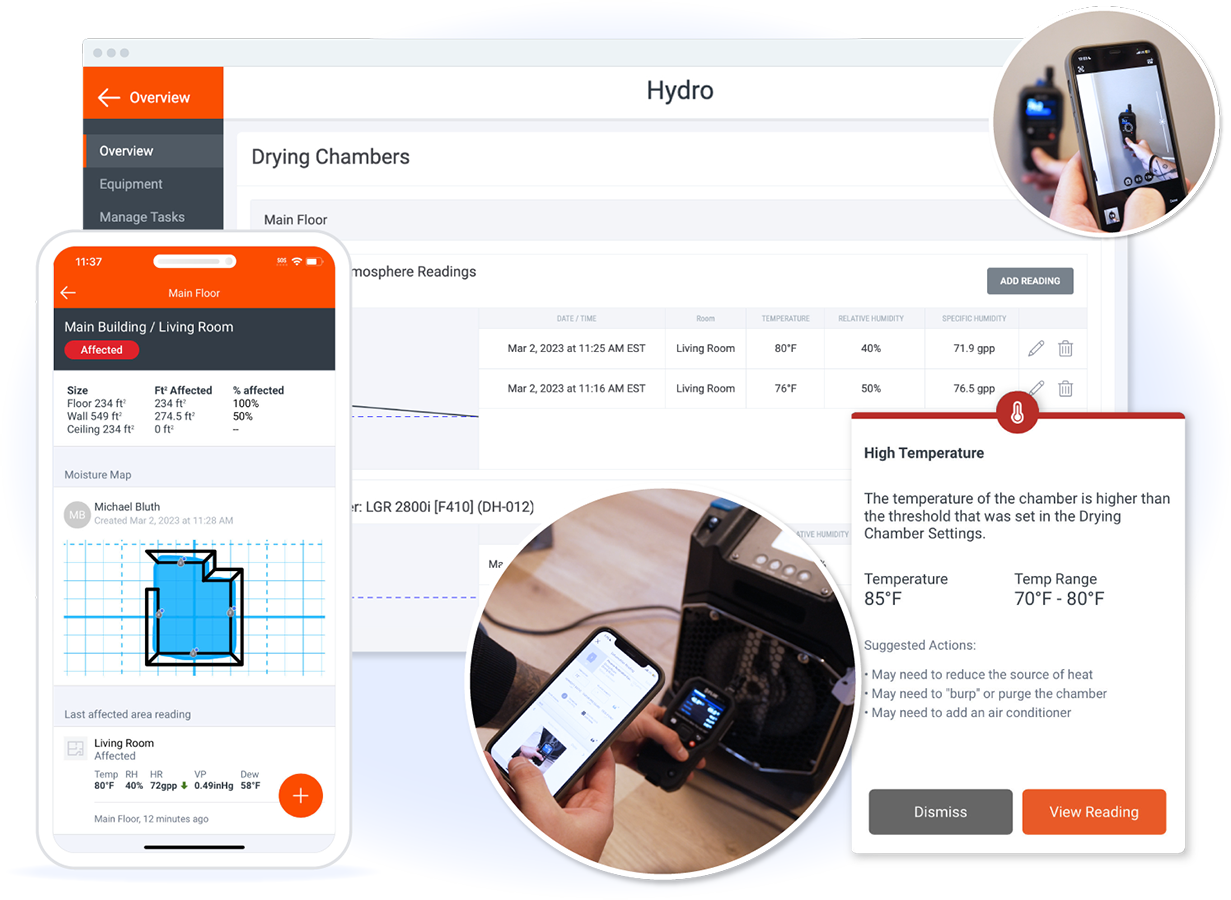

Show proof to get paid.

- Drying logs and moisture maps

Include moisture maps, moisture readings, dehumidifier grain depression readings, and more. - Moisture readings with data integrity

Attach a photo to every moisture reading with automatic GPS metadata, date & time stamps. - Moisture reports

Tell the story of a water loss with an easy-to-read report that takes seconds to create.

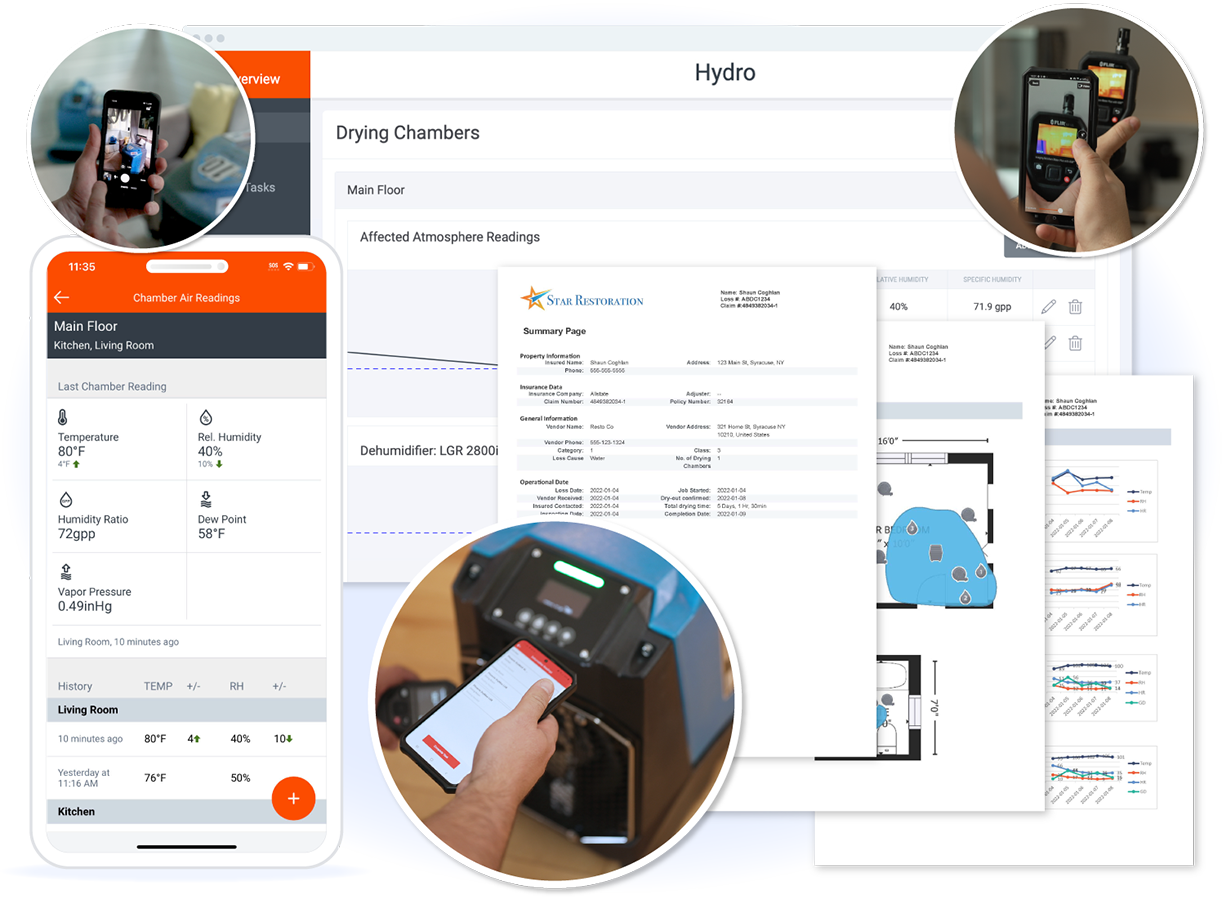

Don't just dry it, justify it.

A paperless field tool that surfaces moisture data in real-time to dry buildings and ensure profitability without pushback.

The Encircle edge

What you can't get anywhere else.

- Field-first design - Documentation done right with fewer clicks.

- Easy sharing - Easily share with teammates, subs, and adjusters.

- No cell service? No problem! - Works even in extreme conditions.

- Works on any device - Works on any smartphone, tablet or desktop.

- Ultimate collaboration tool - Work together for documentation done faster.

- Unlimited data, forever yours - Your data is yours, but kept safe without storage limits.

- Indisputable facts - date, time, and GPS metadata for data integrity.

More Encircle Hydro resources:

Crossroads deploys Encircle Hydro to protect profits on water jobs

Restorers want choice in water mitigation software – not mandates!

MacFawn uses Hydro to stop getting hosed on mit invoices

Frequently asked questions

Below you’ll find answers to some of the questions we get asked most!

Is Hydro an approved moisture analytics tool by carriers and managed repair networks?

The majority of North American carriers and TPAs require documentation that support the IICRC S500 standard, but do not mandate a specific technology provider. Because Encircle Hydro follows the S500 standard for professional water damage restoration, it certainly satisfies this requirement. Many of our customers have told us that they are receiving faster approvals because of the complete data and the professional reports they are able to provide using Hydro.

Crawford Contractor Connection, the largest managed repair network in the United States has approved Hydro as a tool for their 6,000+ network contractors.

We know there are 2 carriers who mandate the use of MICA for water documentation. However, because MICA lacks a mobile friendly solution for field use, documentation is often being done using pen and paper and then later into MICA. This creates delays and gaps that can lead to questions about data integrity and leave restorers vulnerable to estimate scrubbing. To protect their profitability, many restorers are taking advantage of Encircle Hydro in the field to help dry the building and capture the complete documentation right in the moment. Because this data is available in real-time back at the office, it can be entered into MICA even sooner than before, but with the confidence that Encircle holds the proof to justify every action taken on the job and prevent pushback.

Is it difficult to get my team trained on Hydro?

We know how hard it is to find, train, and keep good employees. That’s why we have EncircleU, an online learning platform free for Encircle customers to use to train their teams on Hydro, as well as all of the other features of the Encircle app. Completing EncircleU courses qualifies for IICRC continuing education credits, which is an incredible value for Encircle customers to access free training. You can learn more about EncircleU by visiting the EncircleU page.

How many people can be in the file at one time?

We know that there are a lot of systems out there that only allow one person at the time to work in the job file, but Encircle isn’t one of them. Anyone with access to the job file in Encircle can be working in it, so multiple technicians can be documenting a water loss in the field and at the same time, the PM or office admin can be in the file back at the office and monitor what’s happening in real-time – making your documentation much faster and more efficient.

Do I have to have a good internet connection?

We know that restorers often find themselves in some of the most challenging environments, where a reliable internet connection just isn’t a possibility. That’s why Encircle works offline the same way it works online, so you and your team can document everything as you normally would in the app and when you’re back online, everything will automatically sync. You don’t have to re-enter anything or worry that any information has been lost.